SIMPLE, INTELLIGENT ENERGY MANAGEMENT SYSTEMS

Energize Faster. Operate & Manage

Successfully deploy, operate, and manage your portfolio of renewable energy resources with a commercially-proven ecosystem of integrated software and intelligent hardware.

Since starting as utility-scale solar energy developers and owner operators in 2011, our founders have continually served as leading innovators in the renewables industry.

Our team’s early insight into the challenges of deadline-driven deployment, efficient long term operations, and profitable commercial management has driven Aderis Energy, LLC to design and build reliable solutions that support the fast-paced, growing frontier of the global energy transition.

Looking for an interconnection solution with built-in inrush mitigation?

Check out our patented ClearSky Plus!

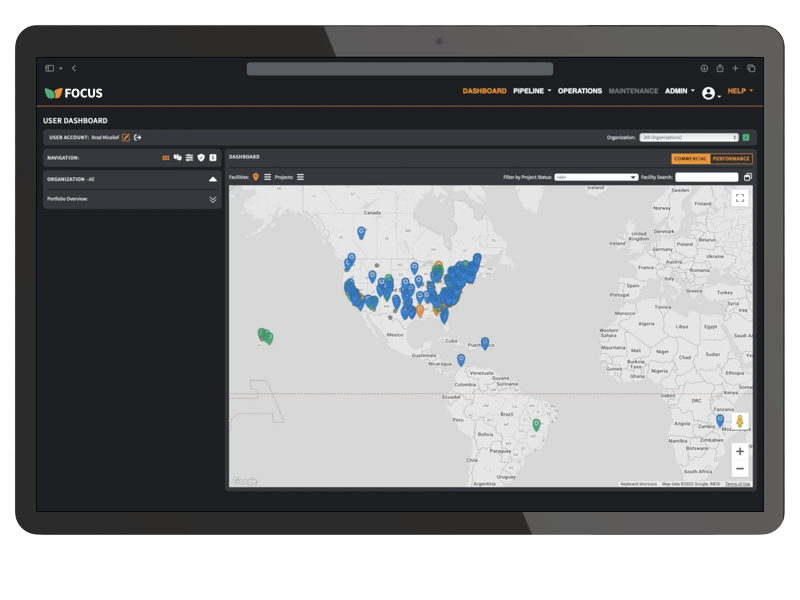

Portfolio Aggregation

▸ MANAGE ASSETS

▸ TRACK ORDERS

▸ OPERATE & MAINTAIN

The Aderis Ecosystem

Monitoring & Control

▸ COLLECT FLAWLESS DATA

▸ DELIVER TRUSTED INFORMATION

▸ ENABLE INFORMED ACTIONS

Energy Automation

▸ GRID INTEGRATION

▸ POWER PLANT CONTROL

▸ MICROGRID & STORAGE EMS

Intelligent Hardware

▸ EXPEDITE PROJECT COMPLETION

▸ DEPLOY TURNKEY SOLUTIONS

▸ LOWER OWNERSHIP COSTS

Wiring Connections

Made Easy.

No more tedious and difficult in-the-field wiring for sensors or telemetry devices. EasyBUS connectors arrive ready to plug, secure, and go.

Customers Benefiting From Aderis Solutions

Aderis Energy is an approved SCADA partner for Erthos, Inc.

See how Acuity™, our intelligent monitoring and control platform, delivers ErthCompatible™ solutions for Erthos’ solar plants.

ErthCompatible™ is a trademark of Erthos, Inc.

Aderis solutions deliver the edge you need to unleash

your renewable energy assets’ power and profitability.

Proven Solutions

Supporting the Energy Transition

DEPLOYED

|

290+ FACILITIES |

2,500+ MW OF PV SOLAR |

390+ MWh of STORAGE |

Get in touch.

Have questions or interested in a demo? Ready to Request a Proposal?

Contact us. Our team is ready to help.